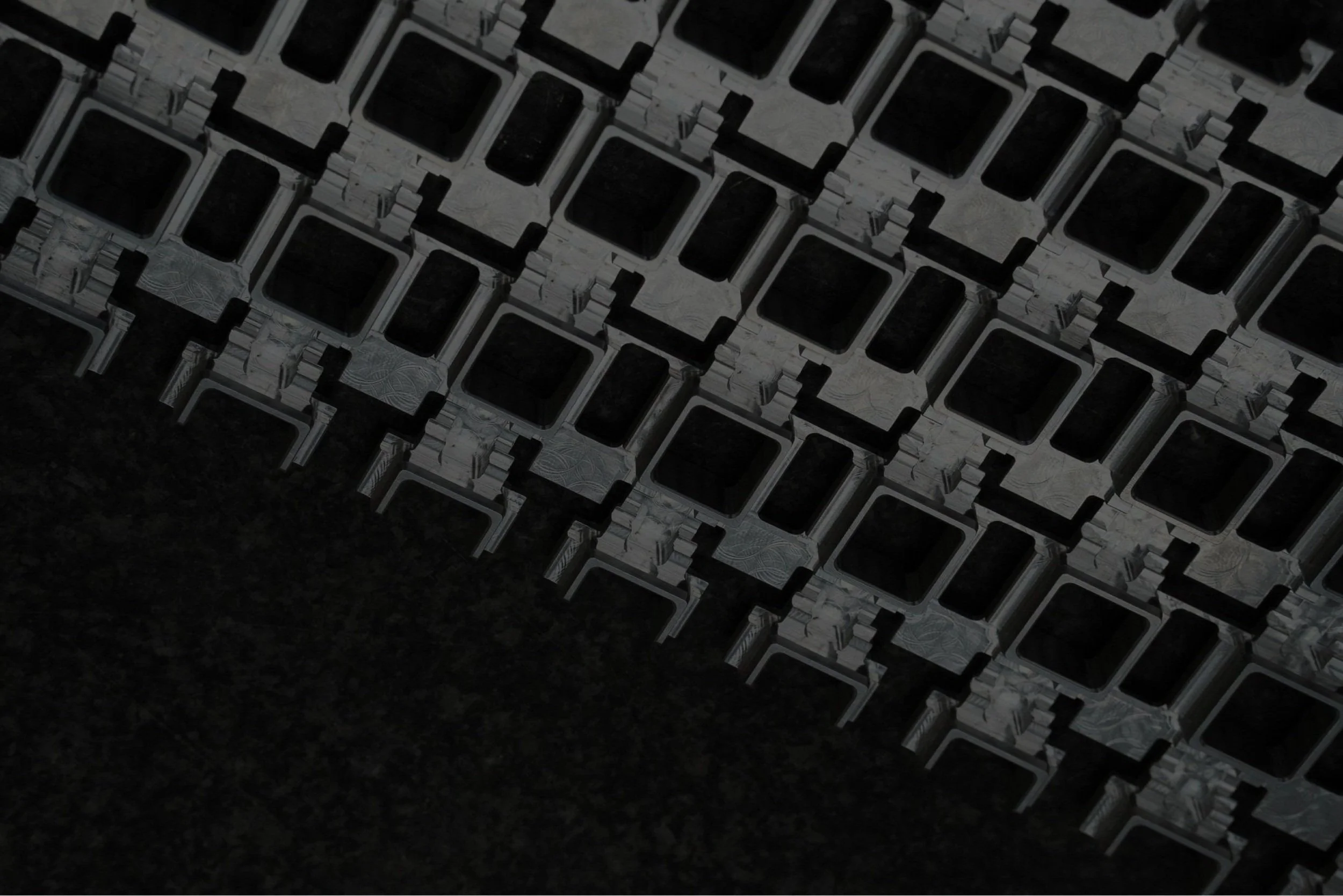

Manufacturing & Design Services

Our manufacturing services fabricate parts from most metal and plastic materials using precision milling, lathe and wire EDM equipment. We make prototype and pre-production parts (EVT, DVT, and PVT) used in product verification. Our manufacturing processes also support our design services in fabricating parts for assemblies.

Milling

From our Haas VF5SS used for large production parts to our Super Mini CNC for smaller precision parts, we have a suite of 7 machines to meet your requirements and fulfill your project in the most cost effective way.

Turning (Lathe)

Our lathe department has a multi range turning capability, from our Citizen CNC Swiss-Type Turning Centers to a HAAS ST 25 CNC Lathe with bar feeder. This allows us to create some of the highest precision complex parts, yet meet the needs of big part, big batch customers.

Wire EDM

We have two Wire EDM machines - a Mitsubishi FX10 which complements the Mitsubishi MV1200S. This allows our EDM department to meet specific machining, tolerance, profile, and feature requirements on specialized parts.

Surface Grinding

The Brown & Sharpe 818 Micromaster Surface Grinder and Mitsui High Tec Manual Surface Grinder allow our incredibly experienced machinists to meet precision tolerance and finish requirements on a variety of different materials.

Screw Machining

A Screw Machine - also known as a Swiss Turning Machine - is a type of lathe that performs extremely well in producing long, thin, complex designs. It is beneficial for production of small parts because it allows for simultaneous turning and milling.

PRO Line Card

Capabilities

CNC & Manual Machining

Large Scale Production

Prototyping and Model Production

Precision Inspection

Design and Optimize for Manufacturing

Reverse Engineering

High Precision Wire EDM

FDM 3D Printing

Form Tool Manufacture and Modification

Computer Aided Modeling/Design and Manufacturing

High Energy Surface Finishing

Surface Grinding

Machines

HAAS VF5SS

HAAS VF4SS

HAAS Super VF3

HAAS Super VF2

HAAS Super Mini Mill

HAAS Mini Mill

Mitsubishi Advance Type 3 Wire EDM

Citizen L5-20VII

HAAS ST25

Bridgeport EZ Path

Sharp ST10

Bridgeport EZ Trak DX

Brown and Sharpe 818 MicroMaster

Mitsui High-Tec

RockRidge Gyra Finish

What can we make for you?

Pro Machine has a dedicated inspection room to verify that the quality of our parts meets customer requirements. This equipment includes CMM, optical comparator, hardness tester and other precision gages and measurement indicators. We have an automated tracking system (shoptech) for orders so that we meet our customers’ JIT requirements and ensure on time delivery.

We have a talented team of machinists and tool makers who have been trained in the latest machining techniques and CNC software programs. Our team can make parts using 2D drawings or 3D solid models.

Volume pricing offered for quantities over 100, 1,000 and 10,000 parts.

-

Normally you will receive your quote within 48 to 72 hours. We can reduce this lead time if you contact us by phone so we can insure we have all the information needed to expedite your quote.

-

We work with a variety of materials including aluminum, plastics, mild steels, tool steels, stainless steels, bronze, brass, copper and titanium.

-

Lead time depends on many factors including material availability, factory loading, number of units needed and part complexity. Typically most orders are filled with in 30 days of purchase order.

-

Yes - we do offer expedited service dependent on volume and resource bandwidth.

-

We work with a wide range of industries including medical devices, computer storage, aerospace, optics, computer networking and the United States military.

-

Our team at PRO can help can suggest material, finish and design changes that will save cost.

-

Absolutely! Please contact us for more information.

Ready to Build?

Our mission is to provide our customers with the highest quality and precision products. We are committed to our customers’ satisfaction by meeting their exacting specifications and consistently delivering on time.